APPLICATIONS

LDH Plough Mixer (The following referred to as Mixer) is new high efficiency powder mixing device developed by our company. The machine is widely used for solid-solid (powder – powder) mixing, solid-liquid (to add liquid into powder) mixing, and wet granulating, drying, concentration and compound process in chemical, pharmaceutical, pesticide, plastic, rubber, fertilizer, construction material, additive of concrete, food, aginomoto, salts, feed additives, dyes, metallurgy, mine industries, etc. It is a multiple functions mixer with high adaptation and wide applications.

STRUCTURE FEATURES

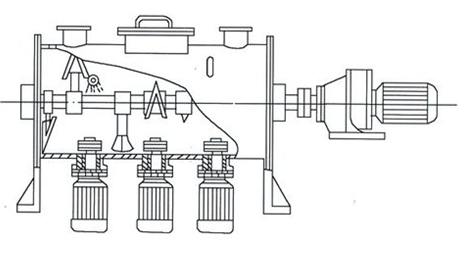

The spray liquid device of the mixer is at the top of the barrel, the spray nozzle adopts agricultural nozzle, with good spraying effect.

Mixer driving part consist of motor, cycloidal pin gear speed reducer, coupler, plough shaft.

The horizontal barrel is for holding material, with several holes on the barrel for discharging and inspection. The supporting seat of plough shaft is fixed on the cover of two ends of the barrel.

The plough shear unit consist of plough shear, plough arm, and main shaft. The plough shear is fixed on the main shaft by plough arm, with Haff structure, which is easy for assemble and disassemble.

There are several shears on plough unit, driven by motor, placed on the side of the barrel.

The discharging valve is at the bottom of the barrel (except continuously discharging), used for closing and discharging material.

The mixer structure is shown in the diagram. It consists of driving part, horizontal barrel, plough unit shaft, shears, discharging valve, spray device and so on.

WORKING PRINCIPLE

After the mixer starts, the plough shears will be driven to rotate by plough shaft, making the material do peripheral turbulence in radius direction along the barrel, at the same time, cast the material in the normal direction of the both sides of the plough shear. When the material cast and doing peripheral turbulence pass by the plough shear unit, it is speedy, strongly dispersed by the plough shear under the high-speed rotating. The material under the compound effect of plough shear and chopper shear, incessantly alternate and disperse to reach uniform mixing and high mixing accuracy in short time.

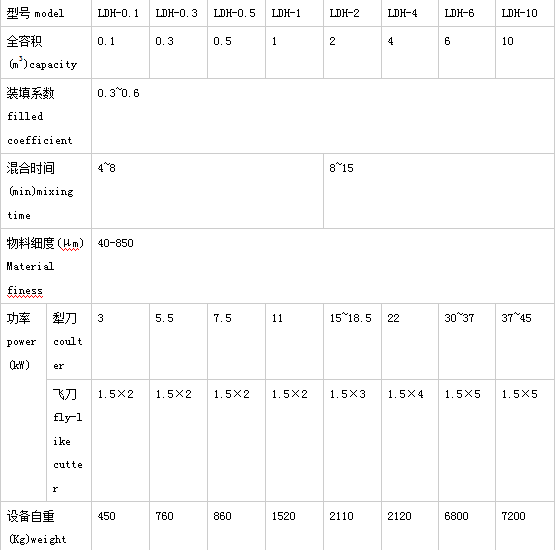

TECHNICAL PARAMETERS

|