APPLICATIONS

It is suitable for drying heat sensitive raw materials that can decompose or polymerize or deteriorate at high temperature. It is widely used in pharmaceutical, chemical, foodstuff and electronic industries.

PRINCIPLE

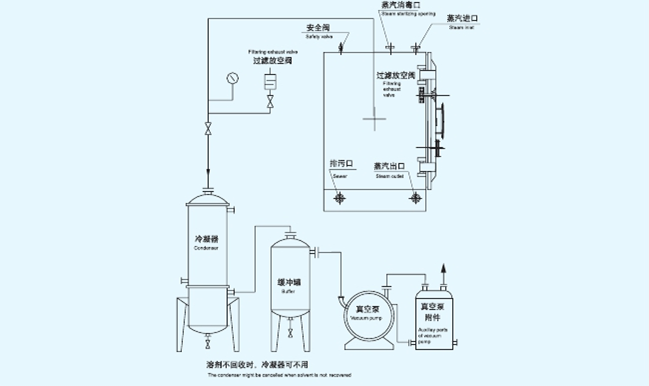

◆ It is well known that vacuum drying is to put raw material under the state of vacuum for heating and drying. If use vacuum to pump air

and humidity out, the dry speed will be faster.

◆ Note: if use condenser, the solvent in raw material can be recovered. If the solvent is water, condenser might be canceled and the in-vestment and energy could be saved.

FEATURES

◆ Under the condition of vacuum, the boiling point of raw material will decrease and make the evaporation efficiency higher. Therefore for

a certain amount of heat transfer, the area of heat transfer for evaporator can be saved.

◆ The heat source for evaporation may be low pressure steam or surplus heat steam.

◆ The heat loss is less.

◆ Before drying, the treatment of disinfection may be carried out. During the period of drying, there is no impurity material mixed. It is in

conformity with the requirement of GMP.

◆ It belongs to static dryer. So the shape of raw material to be dried should not be destroyed.

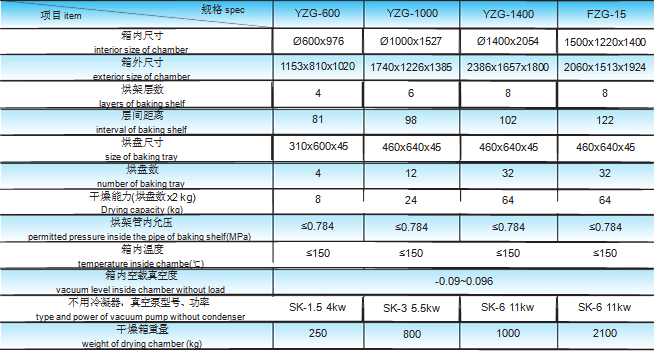

TECHNICAL PARAMETER

The above mentioned date is for reference only. For any special requirements, the factory can provides the service of consultation and design.

All specifications adopt movable structure except YZG600

FLOW CHART

|